- © 2024 Onebeat. All Rights Reserved.

Maximize sell-through. Optimize Inventory. Boost Profitability.

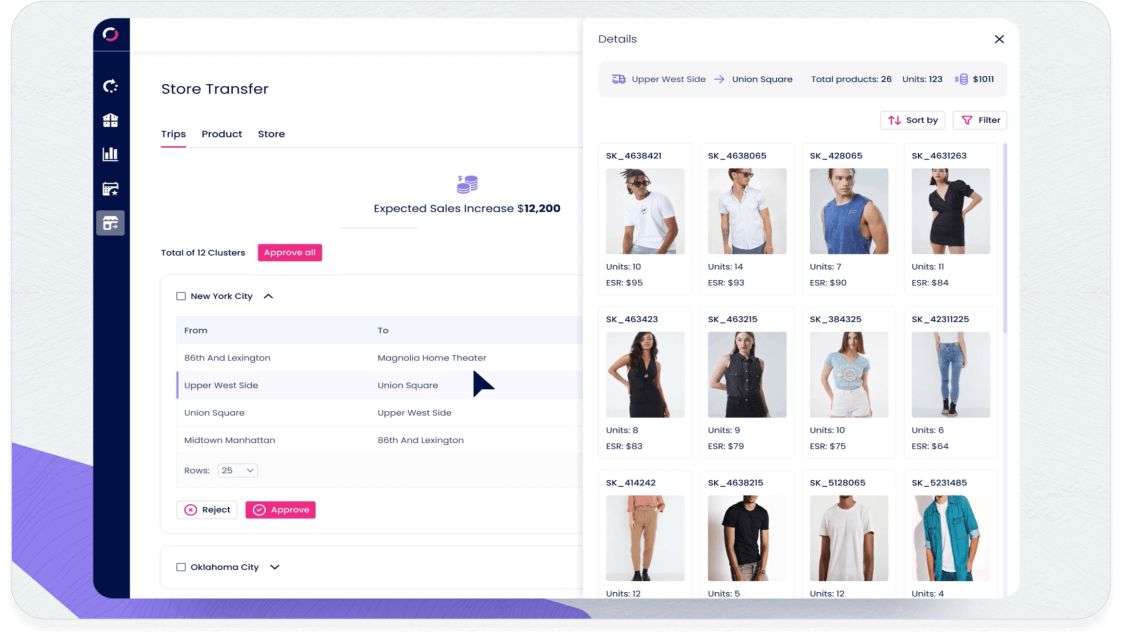

Onebeat reduces retailers’ misallocated inventory by 20% and increases full-price sales by at least 10%.

Onebeat constantly aligns retailers’ inventory with actual demand, enabling retailers to carry 30% less inventory and boost their returns.

Onebeat constantly monitors the assortment effectiveness of every category in each store and adjusts stores’ presentation accordingly, resulting in more attractive displays and higher conversion.

Onebeat synchronizes new product introduction with product liquidation and other demand signals. This synchronization enables retailers to identify and generate more bestsellers and reduce the size of their tail products.

We know the quirks of each industry, and more importantly, we know how to address them.